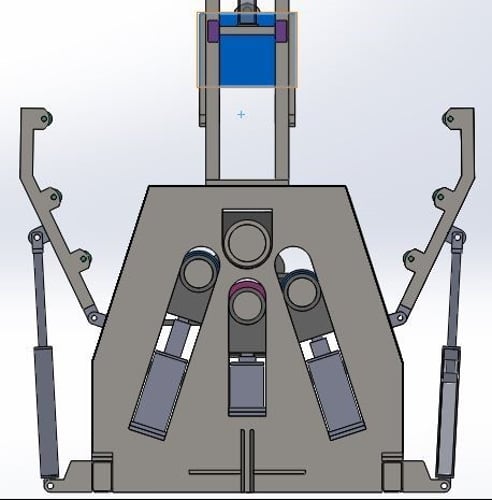

4R SBS 7508 HYDRAULIC 4 ROLLERS PLATE BENDING MACHINE

Technical Specifications:

- Useful working length :7600 mm

- Diameter of top cylinder :Ø420 mm

- Diameter of bottom cylinder :Ø390 mm

- Diameter of side cylinder :Ø340 mm

- Motor power :37 kW

- Rolling speed :4 m/min.

- Weight (approx.) :34000 kg

- Overall dims (L-W-H) :1050x3100x1850 mm

With Pre–Bending ØDia(mm) Thickness(mm)

Min.Inside Diameter 880 6

Min.Inside Diameter 1680 8

Bending ØDia(mm) Thickness(mm)

Min.Inside Diameter 630 6

Min.Inside Diameter 1260 8

*Bending capacities are calculated based on 240 N/mm2 Yield Point.

General Specifications:

- Machine is best for medium / heavy plate bending of cylinders and varying radiused parts.

- Bottom pinching roll with hydraulic positioning. (Top/Down movements) Double pre-bends (at both ends) in one pass is obtained easily.

- Machine can bend roll in shapes of radiused and elliptic by 4 axis NC control system.

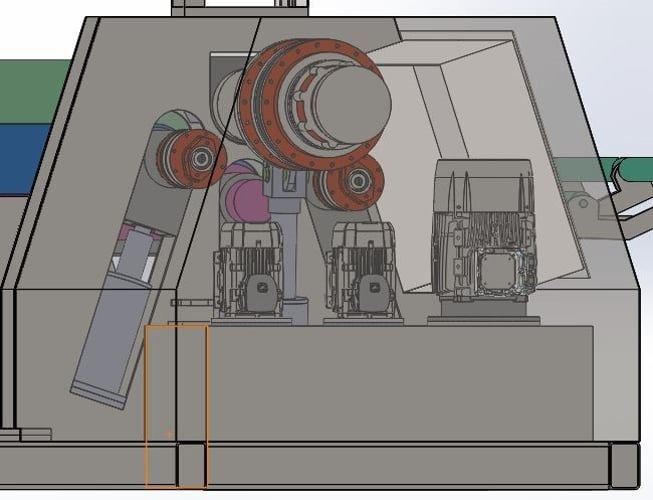

- Top roll is driven by a hydraulic motor coupled to the planetary gearbox (Equipped with overload protection system). Lateral rolls are also driven by hydraulic motor coupled to the planetary gearbox, bottom roll is idle (free).

- Movement of the lateral rolls is carried out by means of pistons.

- Side supports are present at right and left.

- Hydraulic drop end for ease of cylinder removal.

- All operations are conveniently located on an independent Mobile Control Panel.

- SAE 1050-DIN CK45-MKE C 1045 induction hardened rolls are of high tensile carbon steel forgings, heat treated and submitted to non-destructive structure controls. On requirement, rolls can be supplied surface polished.

- Hydraulic elements: Motor & pump group, pressure valves, solenoid valves, oil display and etc. Eaton (UK) components are used.

- Electrical equipment’s: Lovato (Italy).

- Emergency system: Laser sensor barrier around the machine and emergency push button.

- Built according to EC Safety Directives. (CE Mark) and ISO 9000 Certificate.

- User’s Manual in English.

Working System:

In this system, 2 lateral side rollers and 1 bottom roller (pinching roller) are mounted to housings in bronze bushing blocks and these blocks are connected to big hydraulic pistons that supply the up and down movement in linear way. The name of this system is Rectilinear Guide System.

In this system, power is applied by hydraulic motors and planetary gearboxes to top and lateral rolls of the machine.

Drive System:

Top roll is driven by a hydraulic motor coupled to the planetary gearbox (equipped

with overload protection system). Lateral Side Rolls are driven and Bottom Roll is idle.

We powered the lateral side rollers because depending on our experience most important prebending action is made on the lateral side rollers and for this reason the side rollers must be powered in order to keep the force applied to the plate bending point. Bottom roll is free to pinch and support to forward and backward movement of the plate easily without slipping.

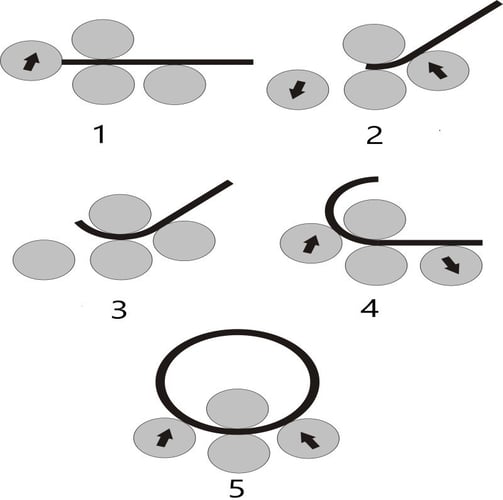

WORKING PRINCIPLE:

Figure 1.

First of all, as shown in Figure 1, the material is aligned between 4 cylinders.

Figure 2.

The material is compressed with the aid of the upper roller and the lower-left cylinder and made pre-bending. Excessive compaction may cause thinner thickness and degradation of the material.

Figure 3.

The motor is actuated and second step of pre-bending made.

Figure 4.

After making the necessary pre-bending process, you may start to the process of bending form any edge desired. After the last pre-bending operation, starting immediately from the last edge, subjected to pre-bending, provides you to achieve better results. Setting of required radius is made with the help of the upper ball, as described in figure 4.

Figure 5.

You may continue to the process of bending, as shown in Figure 5, it is better to bend the material with less passes to obtain the desired profile shape however it is normal to use multiple passes.

Standard Equipment’s:

4 AXIS NC Controller Panel 7.4” Touchscreen

Hydraulic Side Support (2pcs)

Hydraulic Overhead Crane

Cone Rolling Equipment

Manual Pump Central Oiling System

Oil Cooling System

Induction Hardened Rolls (54-60HRC)

Driven Lateral Rolls

Electronic Balancing System for Precision Works on Top Roll Model

Optional Equipment’s:

7 AXIS NC Controller Panel 10.4” Touchscreen :$6000

Automatic Pump Central Oiling :Price on Request

Accumulator System on Hydraulics :Price on Request

Polished Rolls :Price on Reques

Production time:8 Months after order confirmation (exc. Official holidays).

Guarantee / Warranty: During 12 months from delivery date, the machine

is covered by integral guarantee. SBFM supplies a complete assistance including

replacement of defective parts and / or workmanship under normal use and service.

Technician accommodation & travelling expenses and transport cost for warranty parts are on customer's charge.

Payment Term: %50 T / T on order, %50 T / T before shipment.

Installation & Training (Days): Included + (Hotel and Flight Belong to customer) 2 or 3 technicians.

Delivery Terms: Ex-works Konya Factory.

Offer Validity: 30 days.